Folding/Forming

Cambridge Rapid has four press brakes which enable us to match the capacity of the laser and punching machine. We have a full range of tooling and also joggle tooling as well as dutch folding tools to name just a few.

Our Trubend and Safan are 3 metre models and the two Amada’s are 2 metre and 1 metre respectively. We have a range of bar folding equipment which enables us to manufacture round handles and other shapes to supplement our range.

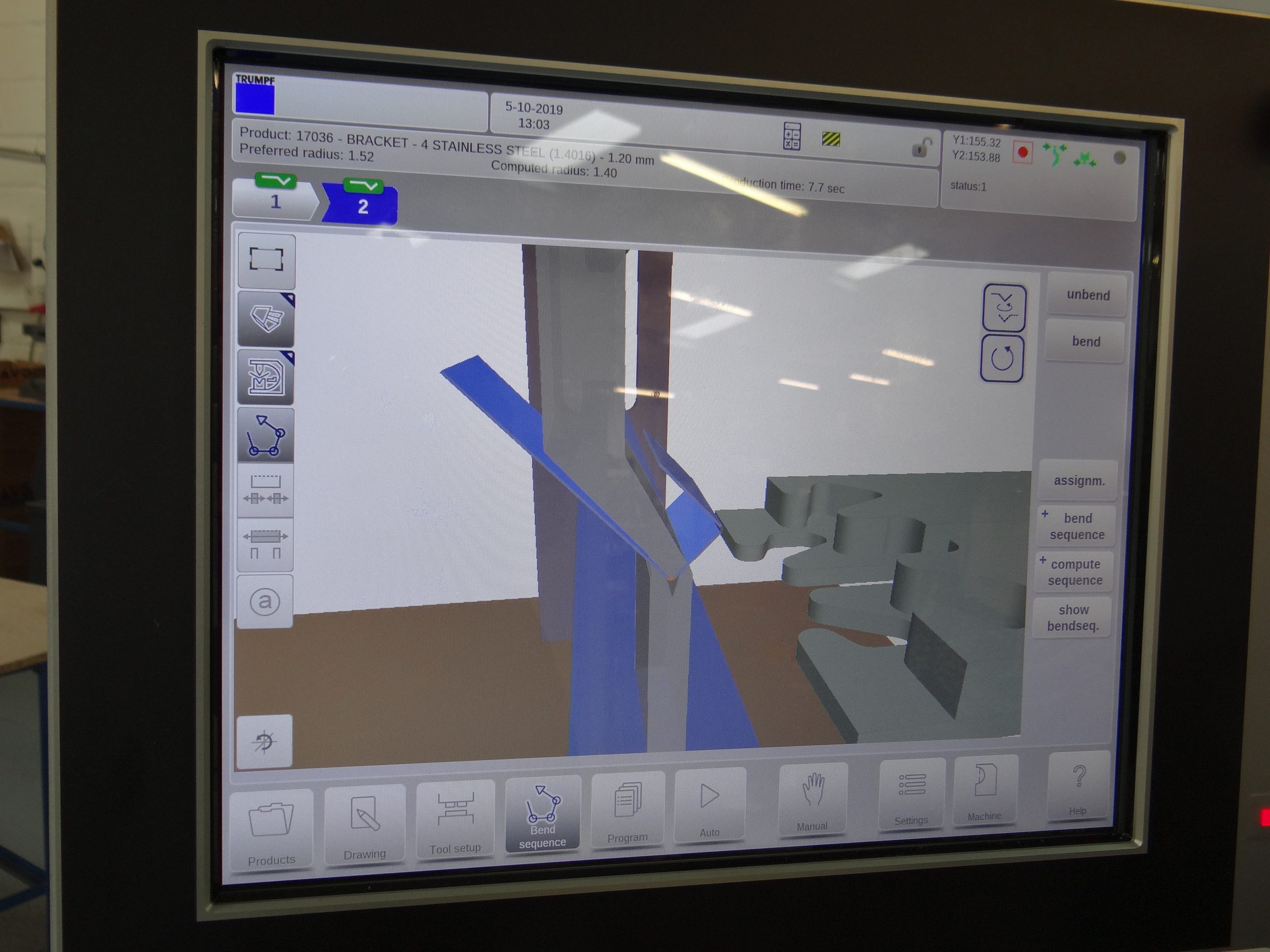

Offline Programming

Our Trubend folder is fully programmable and allows for offline programming. This increases the capacity of our folding department even more.

The 3D graphical representation means that it will highlight any problems before the component is manufactured as well as enabling accurate prediction of folding sizes.

BENDING ROLLERS

Bending Rolls for sheet metal are made in a variety of sizes, and we have four manually operated ones. They are known as pinch-type machines that have two front rollers that are geared together and lightly grip (pinch) the sheet, propelling it through the machine. There is a third ‘free’ roller at the rear of the machine to ‘set’ the sheet to the required radius. Our bending rollers allow us to manufacture round components as well as cones and a variety of shapes.