Punching

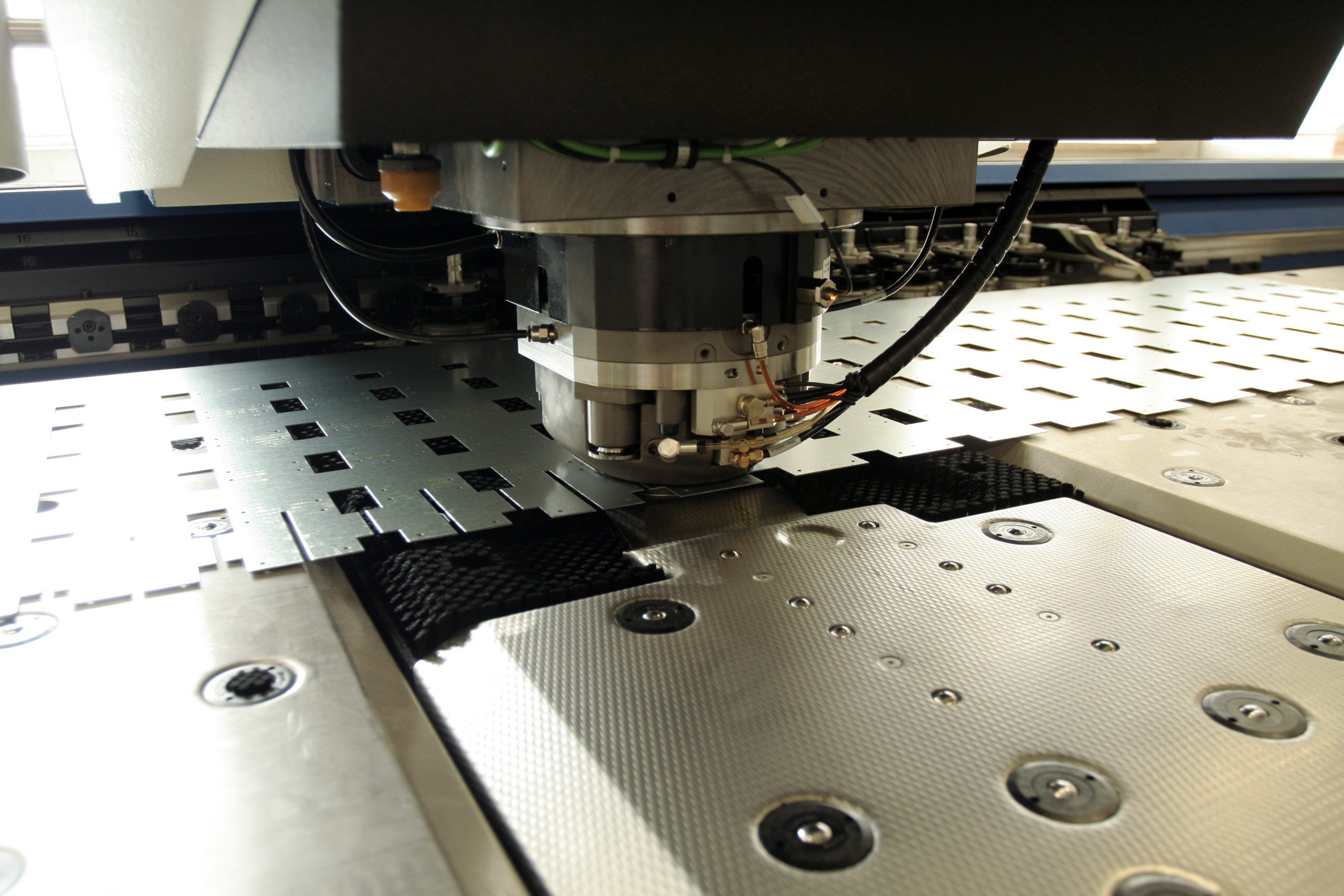

Many people ask why do you need a punch when you have a laser? A punching machine can punch many more holes per minute than a laser! Our punching machine complements our laser to provide a high volume precision process and an unbeatable cost effective solution.

Cambridge Rapid have a Trumpf Trupunch 1000, which has 15 stations along with a 10 station multi-tool. We have a large selection of tooling as well as tooling that is made to bespoke customer requirements.

We undertake high volume blanks for shims, earth tags and washers at a 600 per minute stroke rate. The machine also has a chute for high quantity applications which reduces processing times and cost. Sheets are nested using dedicated software which allows punching at minimal sheet wastage. Our punching machine can emboss, form, engrave and also deburr. We have a full range of tooling and can provide solutions you never thought possible

Engraving/Forming

Our punching machine doesn’t just punch but also engraves product and also produces formed hinges. The engraving gives a different finish to the laser etching on the laser and allows for polishing and other processes to take place.

A sample of an engraved finish can be provided on request